Understanding Thermal Management for High-Power RF Amplifiers

RF power amplifiers operating at 100W continuous output generate significant heat that requires careful thermal management consideration. The efficiency and longevity of these devices depend heavily on maintaining optimal operating temperatures, making cooling solutions a critical aspect of RF amplifier design and implementation.

Modern RF power amplifiers convert electrical energy into radio frequency signals, but this process isn't 100% efficient. A substantial portion of input power becomes waste heat, which must be effectively dissipated to prevent performance degradation and potential system failure.

Thermal Considerations in RF Power Amplifier Design

Heat Generation and Power Dissipation

When operating at 100W continuous output, RF power amplifiers typically exhibit efficiency rates between 50-70%. This means that for a 100W output, the amplifier might draw 150-200W of input power, with the difference being converted to heat. This substantial thermal load requires careful management to maintain optimal performance and prevent component damage.

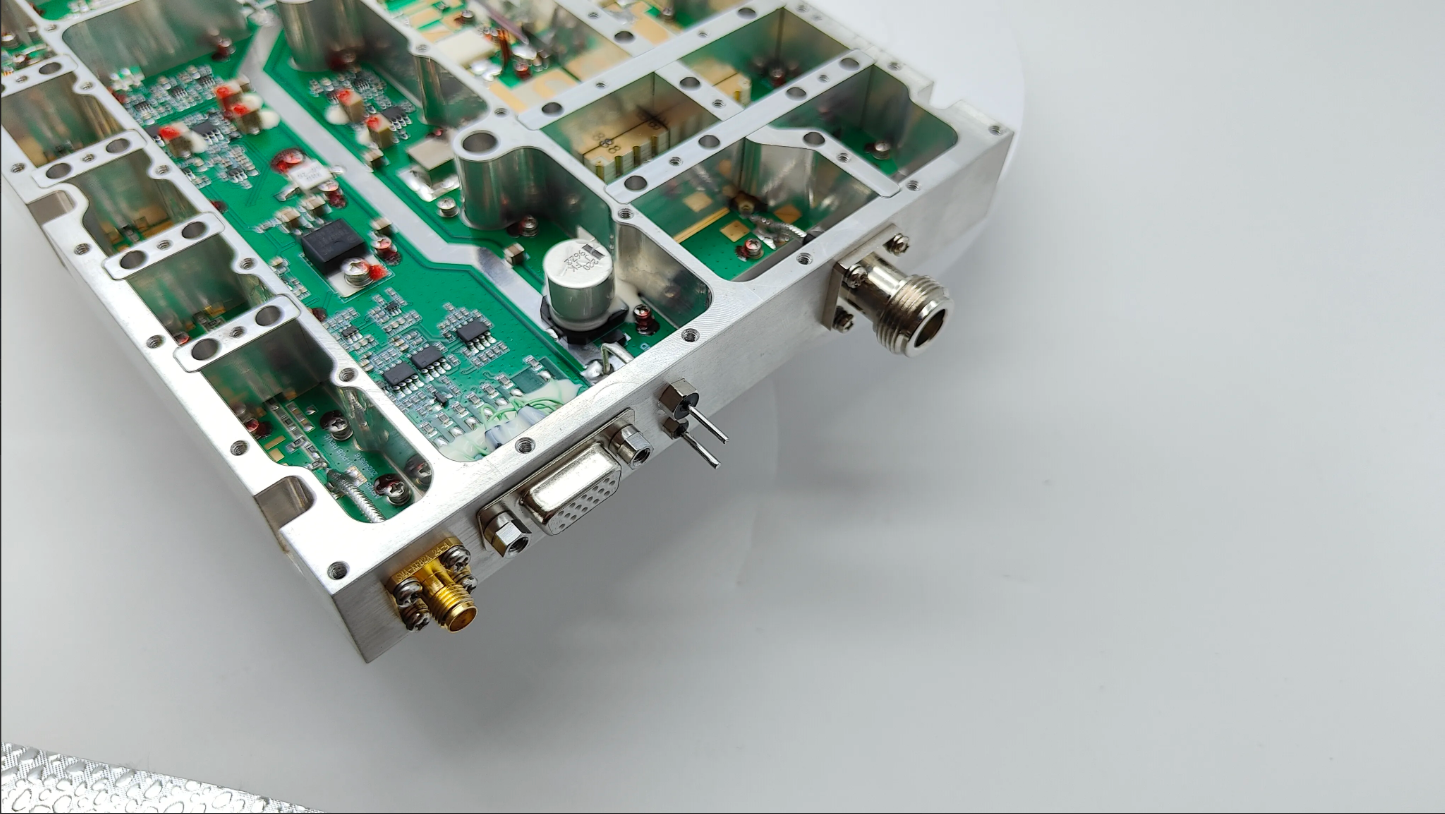

The primary heat-generating components include power transistors, resistive elements, and various semiconductor devices within the amplifier circuit. These components create localized hot spots that can significantly impact the overall thermal profile of the system.

Temperature Impact on Performance

RF power amplifiers are particularly sensitive to temperature variations. Elevated temperatures can lead to decreased gain, reduced linearity, and compromised signal quality. Moreover, sustained high temperatures accelerate component aging and can permanently damage sensitive semiconductor devices.

Operating temperatures above recommended specifications can result in thermal runaway, where increasing temperature leads to higher current draw, creating a dangerous feedback loop that may ultimately destroy the device.

Passive Cooling Solutions and Their Limitations

Natural Convection Methods

Passive cooling relies on natural air movement and heat radiation through heatsinks and thermal spreaders. While effective for lower power applications, passive solutions often prove insufficient for 100W continuous operation. The thermal resistance of passive systems may not adequately dissipate the heat generated at this power level.

Heat sinks with optimized fin designs can improve passive cooling efficiency, but their effectiveness diminishes as ambient temperatures rise or when enclosed in confined spaces.

Thermal Interface Materials

High-quality thermal interface materials enhance heat transfer between components and cooling surfaces. However, even the best thermal compounds and pads cannot overcome the fundamental limitations of passive cooling at high power levels.

The thermal resistance chain from junction to ambient air creates bottlenecks that passive solutions struggle to address effectively.

Active Cooling Requirements and Solutions

Forced Air Cooling Systems

For 100W continuous output operation, active cooling becomes essential in most applications. Forced air cooling using fans or blowers provides significantly improved heat dissipation compared to passive methods. The increased air flow reduces thermal resistance and maintains safer operating temperatures.

Strategic placement of fans and proper air flow management can create effective cooling zones around critical components. Multiple fans may be implemented for redundancy and improved cooling distribution.

Liquid Cooling Alternatives

In scenarios requiring maximum thermal performance, liquid cooling systems offer superior heat dissipation capabilities. While more complex to implement, liquid cooling provides better thermal conductivity and can maintain more stable operating temperatures under heavy loads.

Modern liquid cooling solutions incorporate sealed systems with minimal maintenance requirements, making them increasingly practical for high-power RF applications.

Implementation Best Practices

Temperature Monitoring and Control

Implementing temperature monitoring systems helps prevent thermal damage and ensures optimal performance. Strategic placement of temperature sensors enables real-time monitoring of critical components and automated cooling system adjustment.

Advanced control systems can modulate cooling intensity based on actual thermal loads, optimizing energy efficiency while maintaining safe operating temperatures.

Environmental Considerations

Ambient temperature, altitude, and humidity affect cooling system performance. Proper design accounts for worst-case environmental conditions and includes appropriate safety margins. Installation location and enclosure design significantly impact cooling effectiveness.

Regular maintenance schedules ensure continued cooling system efficiency and prevent degradation of thermal management components.

Frequently Asked Questions

Can passive cooling be sufficient for a 100W RF power amplifier?

While passive cooling might work in ideal conditions with extensive heatsinking and optimal ambient temperatures, it's generally not recommended for reliable 100W continuous operation. Active cooling provides better temperature control and operational stability.

What are the signs of inadequate cooling in RF power amplifiers?

Common indicators include decreased output power, signal distortion, increased noise, intermittent operation, and automatic thermal shutdowns. Regular monitoring can help detect these issues before they cause permanent damage.

How does altitude affect RF power amplifier cooling requirements?

Higher altitudes have lower air density, reducing the effectiveness of air cooling systems. Cooling systems must be designed with altitude considerations in mind, potentially requiring oversized components or alternative cooling methods for high-altitude installations.

EN

EN